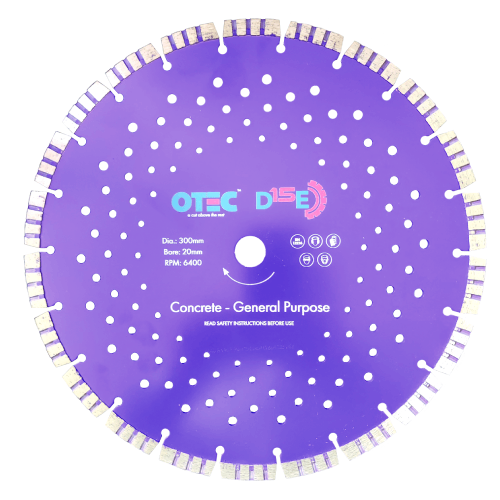

OTEC D15E 300mm Diamond Blade - Concrete & General Purpose (20mm Bore) is a contractor-grade segmented diamond blade designed for fast, reliable cutting of concrete and general masonry on handheld saws, with EN13236 compliance and up to 6400 RPM performance.

-

Blade type: Segmented diamond blade

-

Application: Concrete & general purpose cutting

-

Diameter: 300mm

-

Bore: 20mm

-

Max speed: Up to 6400 RPM

-

Standard: Conforms to EN13236

-

Machine type: Handheld saw compatible

-

Cooling: Cooling holes for improved heat control

-

Performance: Contractor-grade, cost-effective cutting speed and durability

-

Not suitable for: Metal or asphalt

OTEC D15E 300mm Diamond Blade - Concrete & General Purpose (20mm Bore) is a contractor-grade segmented diamond blade designed for fast, reliable cutting of concrete and general masonry on handheld saws, with EN13236 compliance and up to 6400 RPM performance.

-

Blade type: Segmented diamond blade

-

Application: Concrete & general purpose cutting

-

Diameter: 300mm

-

Bore: 20mm

-

Max speed: Up to 6400 RPM

-

Standard: Conforms to EN13236

-

Machine type: Handheld saw compatible

-

Cooling: Cooling holes for improved heat control

-

Performance: Contractor-grade, cost-effective cutting speed and durability

-

Not suitable for: Metal or asphalt

Order 1x to earn 14 FASTPoints

Order to earn 14 FASTPoints

Log in to access trade discountsProduct Name

OTEC D15E 300mm Diamond Blade - Concrete & General Purpose (20mm Bore)

Overview

Key Features & Benefits

- Segmented rim diamond blade for fast cutting speed on concrete and general purpose materials.

- Reliable contractor-grade, cost-effective performance for everyday site cutting tasks.

- 300mm diameter with 20mm bore to suit handheld saws and common spindle setups.

- Cooling holes help reduce heat build-up and support consistent cutting performance.

- Suitable for running at up to 6400 RPM for reliable handheld saw operation.

- Conforms to EN13236 for diamond blade safety and procurement specification.

- Not suitable for cutting metal or asphalt. For these materials, please upgrade to our Premium or Super Premium ranges.

Installation & Applications

Who Is This For?

- Contractors and groundworkers cutting concrete kerbs, slabs, and hard landscaping products.

- Builders needing a reliable general purpose blade for everyday site cutting tasks.

- Hire and site teams specifying EN13236 compliant diamond blades for controlled use.

- Procurement teams sourcing cost-effective contractor-grade blades for ongoing projects.

Competitive Advantages

Why CMT Group?

- Since 1992: long-established OTEC blade range with contractor-led performance heritage.

- Proven track record: high performance and durability with a strong safety reputation over 30+ years.

- Technology-led design: all OTEC blades are engineered for safe running speeds as saw performance increases.

- Safe running speed guidance: 100m/second rating, including 6400 RPM for 300mm blades.

- Procurement-friendly specifications: clear EN compliance, bore sizing, and RPM ratings for confident ordering.

Frequently Asked Questions

What materials is this blade suitable for? It is suitable for concrete and general purpose masonry materials such as kerbs, slabs, medium hard bricks, yorkstone, concrete paviors, and hard nonabrasive concrete products.

What materials is this blade not suitable for? It is not suitable for cutting metal or asphalt. For these materials, please upgrade to our Premium or Super Premium ranges.

What is the maximum RPM? The blade is suitable for running at up to 6400 RPM. Always ensure your machine specification matches the blade rating.

How do I check the blade before use? Inspect for cracking, segment detachment, undercutting, uneven wear, or defects. Confirm rotation direction matches the blade arrow, bore size matches the spindle, wear eye protection, and ensure protective guards are fitted and secure.

Specifications Table

| Product Name | OTEC D15E 300mm Diamond Blade - Concrete & General Purpose (20mm Bore) |

| Product Code | D15E-300/20 |

| Blade Type | Segmented diamond blade |

| Application | Concrete & general purpose cutting |

| Diameter | 300mm |

| Bore | 20mm |

| Max Speed | Up to 6400 RPM |

| Cooling | Cooling holes |

| Standard | EN13236 |

| Machine Type | Handheld saw |

| Not Suitable For | Metal, asphalt |

Key Features

-

Suitable for concrete & general-purpose use

-

300mm Diameter

-

To suit handheld saw

-

Cooling holes

-

Semi-transparent

-

Suitable for running at up to 6400 RPM

Don't think this is the right blade for you? No worries, we have the blade you're looking for!

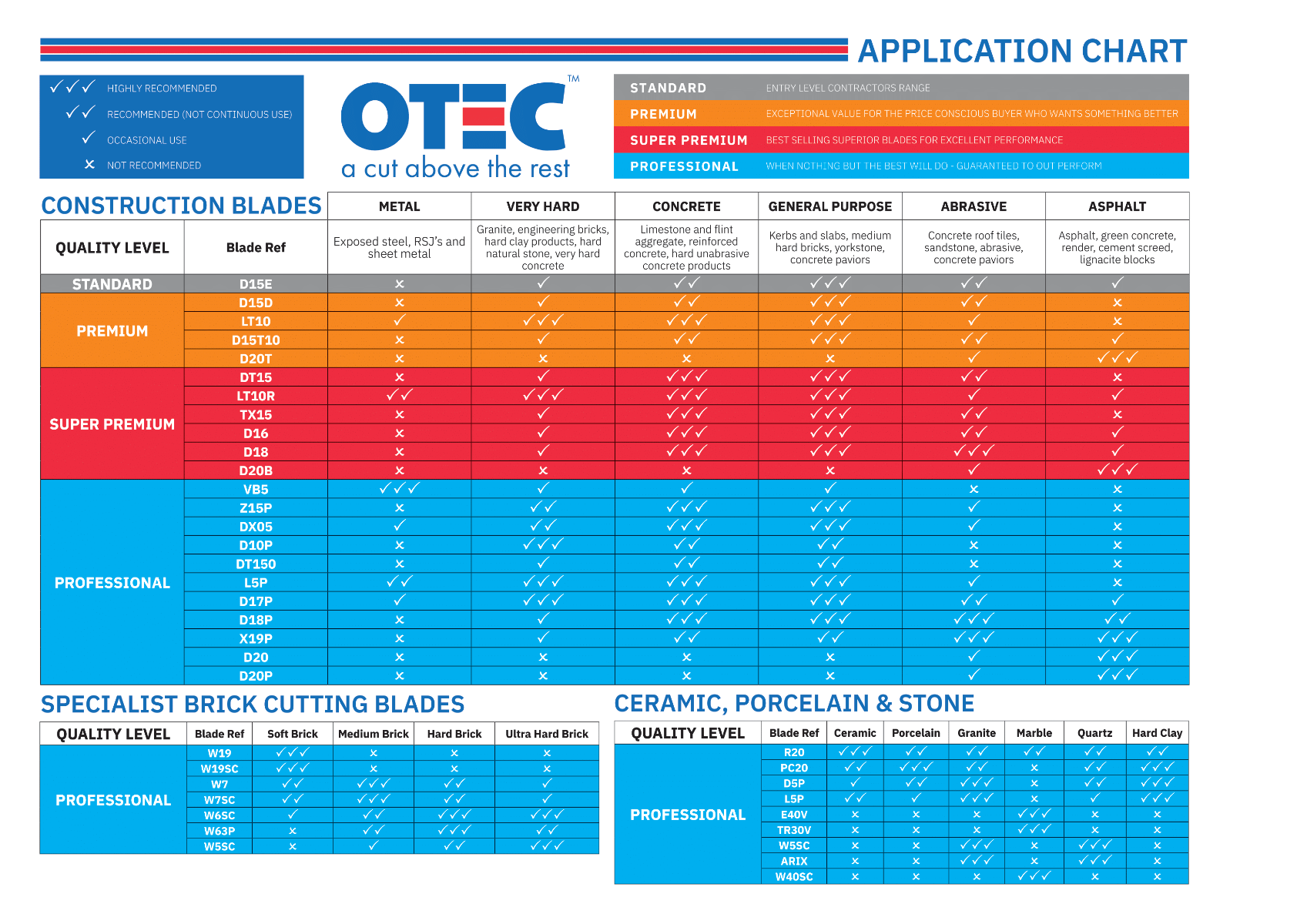

Please use the chart below to find the perfect blade for you - simply put the Blade Ref in the search bar and add it to your order!