OTEC Z15P is a professional concrete diamond blade for contractors who need dependable, fast cutting across concrete and general masonry on UK sites.

• Segment height: 10mm (350mm / 450mm) and 12mm (300mm)

• Diameter options: 300mm, 350mm & 450mm

• Best use for: Concrete, reinforced concrete, limestone, flint aggregate

• Secondary use: Kerbs, slabs, medium–hard bricks, yorkstone, paviors

• RPM: 3400, 5400, 6400

• Installation type: Handheld petrol saws & floor saws (size dependent)

• Compliance: EN13236 diamond blade safety standard

OTEC Z15P Professional Diamond Blade – 10/12mm Segment – Concrete & General Purpose – EN13236 Certified

OTEC Z15P is a professional concrete diamond blade for contractors who need dependable, fast cutting across concrete and general masonry on UK sites.

• Segment height: 10mm (350mm / 450mm) and 12mm (300mm)

• Diameter options: 300mm, 350mm & 450mm

• Best use for: Concrete, reinforced concrete, limestone, flint aggregate

• Secondary use: Kerbs, slabs, medium–hard bricks, yorkstone, paviors

• RPM: 3400, 5400, 6400

• Installation type: Handheld petrol saws & floor saws (size dependent)

• Compliance: EN13236 diamond blade safety standard

Product Name

OTEC Z15P Professional Diamond Blade – 10/12mm Segment – Concrete & General Purpose – EN13236 Certified

Overview

OTEC Z15P is a professional concrete diamond blade for reliable, fast cutting across concrete & general masonry on active UK construction sites.

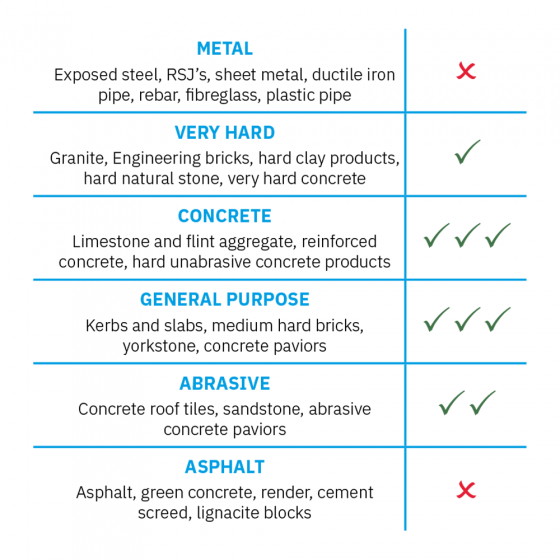

It is primarily designed for concrete, limestone, flint aggregate, reinforced concrete, and hard non-abrasive concrete products, with additional capability for kerbs, slabs, medium to hard bricks, yorkstone, and concrete paviors.

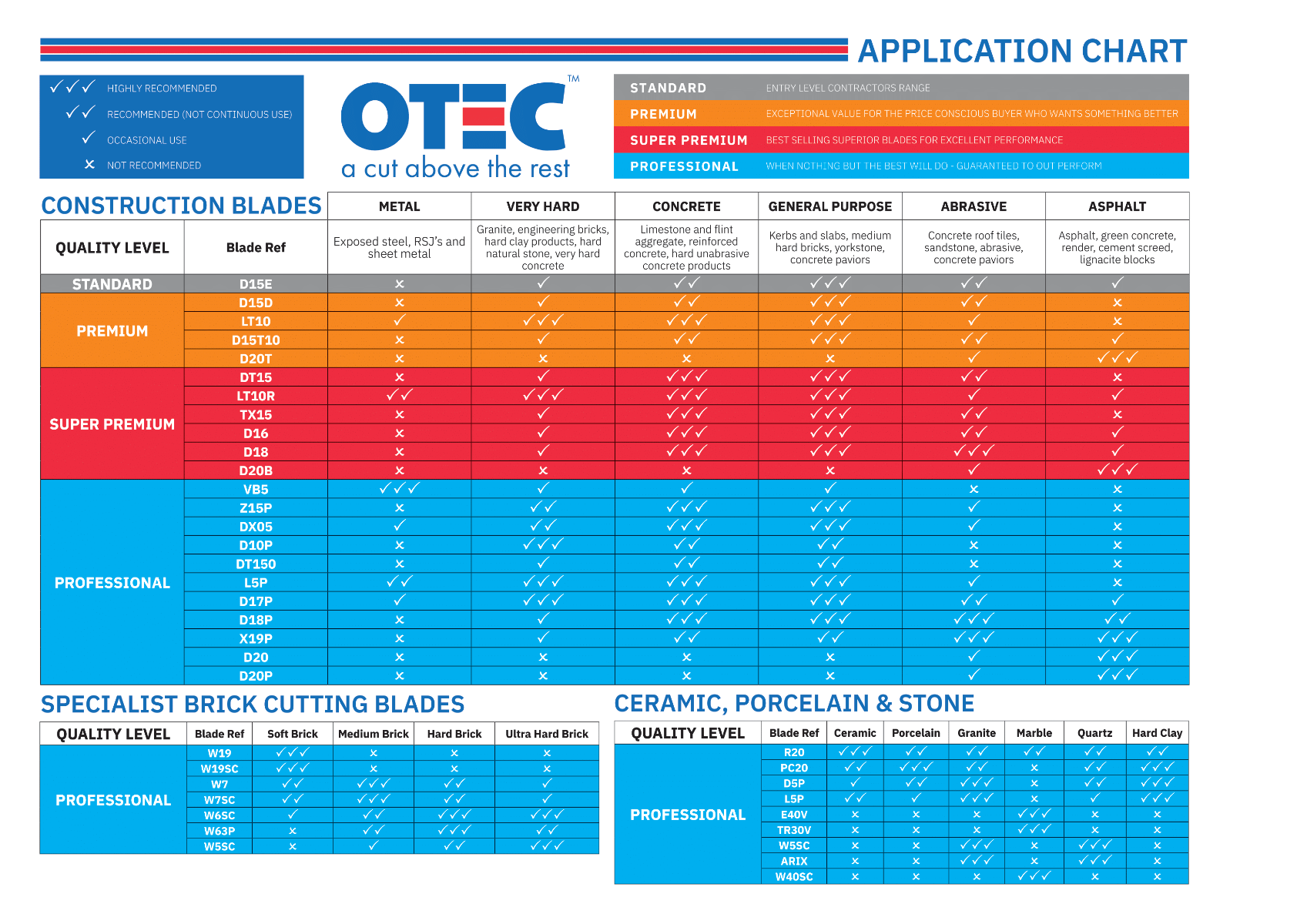

With occasional use only, it can also tackle very hard materials such as granite, hard natural stone, hard clay products, concrete roof tiles, sandstone, and abrasive concrete paviors; it is not suitable for metal or asphalt.

Who Is This For? (Typical UK Site Scenarios)

- Groundworks contractors cutting reinforced concrete bases & edge beams on live housing developments where predictable cutting reduces delays.

- Civil engineering teams using 350mm & 450mm floor saws to cut slabs & access channels where consistent depth supports programme planning.

- Highways and public-realm contractors cutting kerbs, slabs & paviors where clean edges help avoid rework.

- Hire fleets specifying professional-grade blades to reduce misuse, returns & premature wear across mixed users.

- Procurement teams standardising diameters & compliance across multiple sites to reduce substitutions and ordering errors.

How to Specify & Use on Site

How to specify: Select diameter by saw type (300mm for handheld saws; 350mm or 450mm for floor saws), confirm bore compatibility, and ensure the blade rating matches the machine running speed (the 300mm option is suitable for running at up to 6400 RPM).

How to use: Before fitting, inspect for cracks, segment detachment, undercutting, uneven wear, or other defects; align the rotation arrow with spindle direction; use guards and eye protection; avoid excessive cutting force; and allow regular cooling breaks.

- If overheating occurs, the material may be too hard; pause for cooling and reassess suitability.

- A blunt blade can be refreshed by running in a soft abrasive material such as brick or block.

- If wet cutting, ensure a plentiful water supply to both sides of the blade.

For the full list of suitable applications, refer to the catalogue.

Competitive Advantages

Z15P is a dependable professional choice for concrete-led cutting where speed, control, and predictable wear help reduce downtime from unplanned blade changes across varying UK site conditions.

Why CMT Group & Compliance Assurance

CMT Group supports trade buyers and procurement teams with specification-led cutting consumables so you can standardise by diameter, bore, application suitability, and safe running speeds across multiple UK sites.

- Compliance-led specification: this blade conforms to EN13236, supporting safer selection and defensible procurement.

- Risk control: clear application limits (not for metal or asphalt) help reduce misuse and premature wear.

- Procurement-ready supply for ongoing projects, planned works, and multi-site standardisation.

- Fast dispatch from UK-held stock, with 2-hour, same day, or next working day delivery available on most lines, subject to cut-off times and location.

For businesses managing multiple sites or higher-volume spend, CMT Group also provides access to the EDGE Procurement Portal, a free-to-use system designed specifically for construction procurement teams.

- Create site-level contracts with budgets, roles, and approvals to control spend and prevent unauthorised purchasing.

- Lock in agreed pricing, hide prices where required, and manage product visibility by role to reduce disputes.

- Integrations including PunchOut, EDI, and ready-to-go APIs to reduce manual data entry across systems.

- Document Hub for invoices, PODs, delivery notes, and returns to support audits and traceability.

- Construction-led delivery support including live tracking and What3Words location accuracy to reduce misroutes.

Frequently Asked Questions

Is the Z15P suitable for everyday concrete cutting on site?

Yes. It is designed for regular use on concrete and hard non-abrasive concrete products, with additional capability for common masonry such as kerbs, slabs, and paviors.

Can it be used on reinforced concrete?

Yes, reinforced concrete is within the intended application range when used correctly and when the blade rating matches the saw specification.

Which diameter should we specify for handheld vs floor saw work?

Use 300mm for handheld saws and specify 350mm or 450mm for floor saws, then confirm bore and RPM compatibility against the machine requirements.

Is this blade compliant for UK site use?

It conforms to EN13236, the recognised standard for diamond blades used across Europe and the UK, supporting procurement compliance and safer site selection.

Can it be used on asphalt or metal?

No. It is not suitable for asphalt or metal; using it outside its intended range can reduce performance and increase safety risk.

What should we do if cutting slows down or the blade feels blunt?

Do not force the cut. Allow cooling breaks and refresh the blade in a soft abrasive material such as brick or block; if issues persist, stop use and consult your supplier.

Specifications Table

| Product Name | OTEC Z15P Professional Diamond Blade – 10/12mm Segment – Concrete & General Purpose – EN13236 Certified |

| Product Code | Z15P |

| Primary Application | Concrete, limestone, flint aggregate, reinforced concrete, hard non-abrasive concrete products |

| Secondary Application | Kerbs, slabs, medium to hard bricks, yorkstone, concrete paviors |

| Occasional Use | Granite, hard natural stone, hard clay products, concrete roof tiles, sandstone, abrasive concrete paviors |

| Not Suitable For | Metal, asphalt |

| Diameter Options | 300mm (handheld saws), 350mm & 450mm (floor saws) |

| Segment Height | 12mm (300mm) / 10mm (350mm & 450mm) |

| Max RPM (300mm) | Up to 6400 RPM |

| Compliance | EN13236 |

Product Variations Table

| Variation Code | Diameter | Typical Saw Type | Segment | Selection Notes |

| Refer to catalogue | 300mm | Handheld saw | 12mm | General concrete cutting; ensure bore & RPM match the machine (up to 6400 RPM) |

| Refer to catalogue | 350mm | Floor saw | 10mm | Slab and channel cutting where depth consistency matters |

| Refer to catalogue | 450mm | Floor saw | 10mm | Longer runs and heavier cuts on slabs and access routes |

Note: variation codes and bore options are size-dependent; please refer to the catalogue for the exact variant required.

We really appreciate feedback from customers who have purchased and used this blade on site. Your comments help us refine our product ranges and specifications, and also support other trade buyers in choosing the right solution for their work.

Don't think this is the right blade for you? No worries, we have the blade you're looking for!

Please use the chart below to find the perfect blade for you - simply put the Blade Ref in the search bar and add it to your order!