Asphalt diamond blade developed for professional contractors cutting asphalt, green concrete, render, cement screed & lignacite blocks on UK roadworks and infrastructure projects.

• Designed for high-performance asphalt and abrasive road cutting

• Undercut protected segment design to manage steel core wear

• 10mm segment height

• Available in 300x20mm size

• EN13236 compliant

Asphalt Diamond Blade – Professional Plus – 10mm Segment – Undercut Protected – 300x20mm – OTEC D20P

Asphalt diamond blade developed for professional contractors cutting asphalt, green concrete, render, cement screed & lignacite blocks on UK roadworks and infrastructure projects.

• Designed for high-performance asphalt and abrasive road cutting

• Undercut protected segment design to manage steel core wear

• 10mm segment height

• Available in 300x20mm size

• EN13236 compliant

Order 1x to earn 120 FASTPoints

Order to earn 120 FASTPoints

Log in to access trade discountsAsphalt Diamond Blade – Professional Plus – 10mm Segment – Undercut Protected – 300x20mm – OTEC D20P is developed for professional use on UK roadworks and infrastructure projects where asphalt and abrasive materials place increased demands on blade durability.

It is intended for contractors cutting asphalt, green concrete, cement screed, render, lignacite blocks and abrasive concrete products. The Professional Plus configuration supports improved wear resistance and longer usable blade life when compared to standard professional asphalt blades.

The D20P is not suitable for metal, very hard materials or general masonry. It should be specified specifically for asphalt-led and high-abrasion applications.

Looking for a different fit?

View the OTEC D20 for alternative sizes, all engineered with the Professional abrasive-resistance technology.

✓ Professional Plus range designed for extended service life

✓ Optimised for continuous asphalt cutting on roadworks and highways

✓ Wedge undercut protection helps prevent premature steel centre erosion

✓ Maintains stable cutting behaviour in highly abrasive conditions

✓ Suitable for green concrete and other early-age abrasive materials

✓ Supports reduced downtime during repetitive cutting tasks

✓ Developed for consistent daily professional site use

Specifications Table – OTEC D20P

| Specification | Details |

|---|---|

| Product Name | Asphalt Diamond Blade – Professional Plus – 10mm Segment – Undercut Protected – 300x20mm – OTEC D20P |

| Product Code | D20P |

| Diameter | 300mm |

| Bore Size | 20mm |

| Segment Height | 10mm |

| Segment Type | Undercut protected |

| Primary Application | Asphalt |

| Secondary Application | Abrasive materials and green concrete |

| Not Suitable For | Metal, very hard materials, general masonry |

| Safety Standard | EN13236 |

| Use Environment | UK roadworks and infrastructure sites |

Variations Table – OTEC D20P

| Diameter | Bore | Max RPM | Variation Code |

|---|---|---|---|

| 300mm | 20mm | 6400 rpm | D20P-300/20 |

! Max RPM must always be verified against machine rating before use.

Recommended Saw Type by Blade Size – OTEC D20P

| Blade Size | Bore | Recommended Saw Type | Typical Site Use |

|---|---|---|---|

| 300mm | 20mm | Petrol cut-off saw | Asphalt repairs & reinstatement |

The Asphalt Diamond Blade – Professional Plus – 10mm Segment – Undercut Protected – 300x20mm – OTEC D20P is suitable for:

-

Asphalt road and pavement cutting

-

Utility trenching and reinstatement

-

Green concrete removal

-

Cement screed and render cutting

-

Lignacite blocks and abrasive concrete products

Material Suitability Table – OTEC D20P

| Material Category | Typical Materials Included | Suitability |

|---|---|---|

| Metal | Exposed steel, RSJs, sheet metal, ductile iron pipe, rebar, fibreglass, plastic pipe | ❌ |

| Very Hard | Granite, engineering bricks, hard clay products, hard natural stone, very hard concrete | ❌ |

| Concrete | Limestone and flint aggregate, reinforced concrete, hard unabrasive concrete products | ❌ |

| General Purpose | Kerbs and slabs, medium hard bricks, yorkstone, concrete paviors | ❌ |

| Abrasive | Concrete roof tiles, sandstone, abrasive concrete paviors | ✔ |

| Asphalt | Asphalt, green concrete, render, cement screed, lignacite blocks | ✔✔✔ |

Before use:

Ensure the blade type and specification are suitable for the material being cut. Inspect for cracking, segment detachment, undercutting of the steel core or uneven wear. Confirm correct rotation direction and bore compatibility with the machine spindle. Wear appropriate PPE and ensure machine guards are correctly fitted.

During use:

Do not apply excessive force. Allow the blade to cut at its designed speed and take regular cooling breaks. If cutting performance drops significantly, reassess material suitability. Secure the material firmly and regularly inspect the blade for damage.

Wet cutting:

If wet cutting is used, ensure a continuous and adequate water supply to both sides of the blade.

Is the D20P suitable for asphalt cutting?

Yes. The D20P is designed specifically for asphalt and highly abrasive materials.

Can this blade be used on green concrete?

Yes. Green or newly laid concrete falls within its intended abrasive application range.

How does the D20P differ from the standard D20?

The D20P offers extended service life and improved durability for repetitive asphalt cutting tasks.

Is the D20P suitable for reinforced concrete?

No. It is not intended for reinforced or very hard concrete.

Which machines can the D20P be used with?

It is suitable for petrol cut-off saws compatible with a 300mm blade and 20mm bore, within rated RPM limits.

Is this blade compliant with UK safety standards?

Yes. The D20P conforms to EN13236.

Don't think this is the right blade for you? No worries, we have the blade you're looking for!

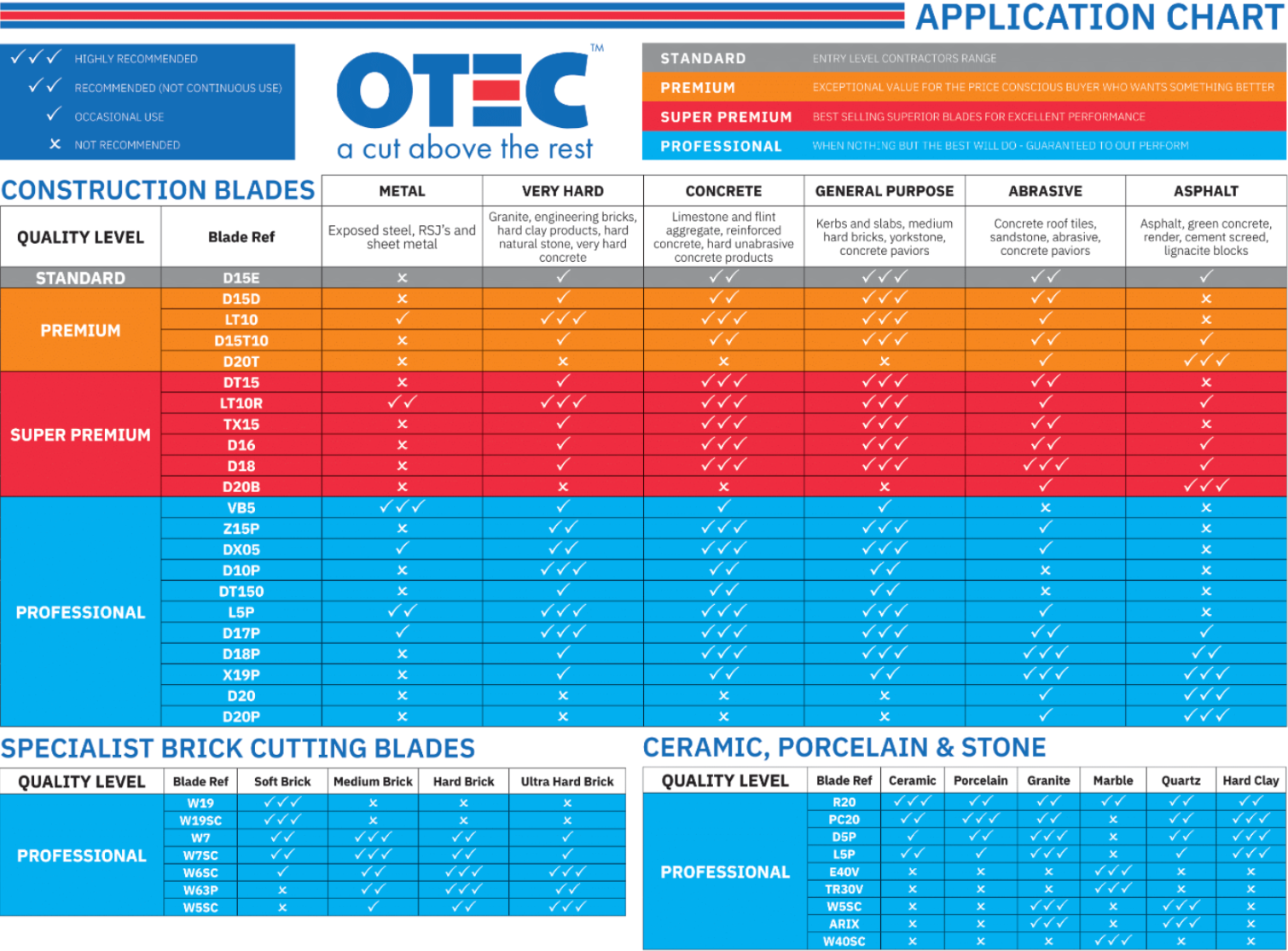

Please use the chart below to find the perfect blade for you - simply put the Blade Ref in the search bar and add it to your order!