These super-premium diamond blades are used for fast, controlled cutting of concrete and hard construction materials where extended blade life and lowest cost-per-cut are required on demanding sites.

• RPM: 6400

• Diameter / bore: 300mm diameter with 20mm bore

• Segment height: 15mm segmented rim

• Application: Concrete; reinforced concrete; hard non-abrasive materials

• Cooling: Integrated cooling holes

• Performance focus: Fast cutting speed with extended wear life

• Compliance: EN13236

These super-premium diamond blades are used for fast, controlled cutting of concrete and hard construction materials where extended blade life and lowest cost-per-cut are required on demanding sites.

• RPM: 6400

• Diameter / bore: 300mm diameter with 20mm bore

• Segment height: 15mm segmented rim

• Application: Concrete; reinforced concrete; hard non-abrasive materials

• Cooling: Integrated cooling holes

• Performance focus: Fast cutting speed with extended wear life

• Compliance: EN13236

Order 1x to earn 52 FASTPoints

Order to earn 52 FASTPoints

Log in to access trade discountsProduct Name

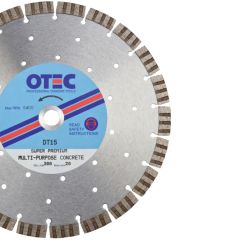

OTEC TX15 Super Premium Diamond Blade - 15mm Segment - Concrete & Universal - Lowest Cost-Per-Cut

Overview

The OTEC TX15 is a super premium diamond blade engineered for fast, controlled cutting of concrete and hard non-abrasive construction materials where productivity and cost-per-cut matter. Featuring a 15mm segmented rim, this blade is designed to deliver extended wear life, reduced blade changes, and consistent cutting performance on demanding construction sites.

Key Features & Benefits

- 15mm super premium segmented rim delivers extended service life and reduced tool change frequency.

- Fast cutting performance on concrete, limestone, flint aggregate, and reinforced concrete.

- integrated cooling holes improves safety and cutting stability.

- Semi-transparent steel core improves cut-line visibility during operation.

- Optimised for lowest cost-per-cut on high-volume concrete cutting tasks.

- Conforms to EN13236 for diamond blade safety and specification-led procurement.

Installation & Applications

Fit the blade to a compatible cut-off saw, ensuring the 20mm bore matches the machine spindle and the rotation direction aligns with the arrow on the blade. Apply steady cutting pressure and allow regular cooling breaks during extended cutting cycles.

- Concrete, reinforced concrete, and in-situ concrete

- Limestone and flint aggregate concrete products

- Kerbs, slabs, concrete paviors, and yorkstone

- Medium to hard bricks and general construction materials

This blade is not suitable for metal, very hard materials, or asphalt. For a full list of compatible applications, refer to the OTEC product catalogue.

Who Is This For?

- Concrete and groundworks contractors requiring fast cutting and long blade life

- Site teams cutting reinforced and hard concrete products daily

- Hire fleets specifying super-premium blades for durability and reduced downtime

- Procurement teams focused on lowest cost-per-cut and long-term value

Competitive Advantages

The TX15 is optimised specifically for concrete and hard non-abrasive products. The 15mm segment height delivers extended wear life, while the semi-transparent cooling design improves visibility and cutting control, helping reduce operator fatigue and blade replacement costs.

Why CMT Group?

CMT Group supplies specification-led diamond blades that allow contractors and procurement teams to select cutting tools by segment height, material focus, and compliance rather than marketing claims.

- Procurement-focused blade ranges engineered for predictable site performance.

- Bulk and multi-site supply support for frameworks and planned works.

- Clear EN compliance and RPM ratings to support safe specification.

- Fast dispatch from UK-held stock, with 2-hour, same day, or next working day delivery available on most lines, subject to cut-off times and location.

SiteHive.ai supports centralised ordering, approvals, and delivery tracking for diamond tooling across multiple sites.

Frequently Asked Questions

Can I use this diamond cutting blade on all materials? No. This blade is designed primarily for concrete and hard non-abrasive materials. It can also be used on kerbs, slabs, medium hard bricks, yorkstone, and concrete paviors.

What size is this diamond blade? The blade is 300mm in diameter with a 20mm bore and a 15mm segment height. Always check your saw specification before purchase.

What quality level is the TX15 blade? The TX15 sits in the OTEC super premium range and is specified for high-performance concrete cutting where durability and lowest cost-per-cut are required.

Specifications Table

| Product Name | OTEC TX15 Super Premium Diamond Blade - 15mm Segment - Concrete & Universal - Lowest Cost-Per-Cut |

| Product Code | TX15-300/20 |

| Diameter | 300mm |

| Bore Size | 20mm |

| Segment Height | 15mm |

| Segment Type | Segmented |

| Max RPM | 6400 RPM |

| Max Peripheral Speed | 100 m/s |

| Compliance | EN13236 |