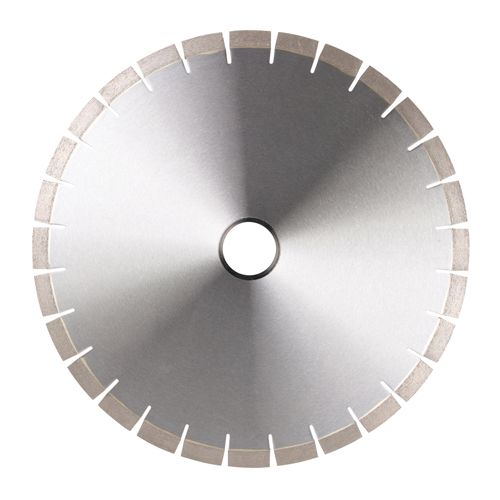

Quartz and granite cutting diamond blade developed for professional users cutting dense natural stone materials on UK bridge saw and fabrication projects.

• Designed for controlled cutting in dense granite and quartz materials

• ARIX auto array segment technology for consistent cutting performance

• 15mm auto array segment height

• Available in 400 & 450mm x 50/60 sizes with multi-bore configuration

• Suitable for bridge saw use

• EN13236 compliant

Quartz & Granite Cutting Diamond Blade – Professional – ARIX Technology – 15mm Auto Array Segment – OTEC ARIX

Quartz and granite cutting diamond blade developed for professional users cutting dense natural stone materials on UK bridge saw and fabrication projects.

• Designed for controlled cutting in dense granite and quartz materials

• ARIX auto array segment technology for consistent cutting performance

• 15mm auto array segment height

• Available in 400 & 450mm x 50/60 sizes with multi-bore configuration

• Suitable for bridge saw use

• EN13236 compliant

Quartz & Granite Cutting Diamond Blade – Professional – ARIX Technology – 15mm Auto Array Segment – OTEC ARIX is designed for professional stone fabricators working with dense granite and quartz materials where consistency and durability are critical.

The ARIX auto array segment construction positions diamond grains in a structured 3D pattern to support uniform wear and stable cutting behaviour. This helps maintain consistent cutting performance over extended use, making the blade suitable for demanding bridge saw applications in stone processing environments.

The ARIX blade is not suitable for ceramic, porcelain, marble or hard clay materials. It should be specified exclusively for granite and quartz cutting tasks.

Need a different size or use case?

View the complete OTEC range, including the OTEC W5SC - our professional alternative blade .

Things to consider:

Always use personal protective equipment to ensure safety for you and others. CMT Group offers a comprehensive range of PPE products like hand protection, eye protection, respiratory equipment, & ear protection equipment to suit your needs.

✓ ARIX auto array diamond technology for controlled, uniform wear

✓ Structured diamond placement supports stable cutting behaviour

✓ Designed for dense granite and quartz materials

✓ Maintains consistent performance over prolonged cutting cycles

✓ Suitable for precision stone fabrication work

✓ Intended for professional bridge saw operation

Specifications Table – OTEC ARIX

| Specification | Details |

|---|---|

| Product Name | Quartz & Granite Cutting Diamond Blade – Professional – ARIX Technology – 15mm Auto Array Segment – OTEC ARIX |

| Product Code | ARIX |

| Segment Height | 15mm |

| Segment Type | Auto array (ARIX technology) |

| Primary Application | Granite and quartz |

| Secondary Application | — |

| Not Suitable For | Ceramic, porcelain, marble, hard clay, reinforced concrete, metal |

| Safety Standard | EN13236 |

| Recommended Machine Type | Bridge saw |

| Use Environment | UK stone fabrication and processing facilities |

Variations Table – OTEC ARIX

| Diameter | Bore | Max RPM | Variation Code |

|---|---|---|---|

| 400mm | 50/60mm | —* | ARIX-400 |

| 450mm | 50/60mm | —* | ARIX-450 |

! Max RPM must always be verified against machine rating before use.

Recommended Saw Type by Blade Size – OTEC ARIX

| Blade Size | Bore | Recommended Saw Type | Typical Site Use |

|---|---|---|---|

| 400mm | 50/60mm | Bridge saw | Granite and quartz slab cutting |

| 450mm | 50/60mm | Bridge saw | Large format granite and quartz processing |

Application:

The Quartz & Granite Cutting Diamond Blade – Professional – ARIX Technology – 15mm Auto Array Segment – OTEC ARIX is suitable for:

- Granite slab cutting

- Quartz surface processing

- Stone fabrication workshops

- Precision bridge saw cutting

- Continuous production cutting environments

Material Suitability Table – OTEC ARIX

| Ceramic | Porcelain | Granite | Marble | Quartz | Hard Clay |

|---|---|---|---|---|---|

| ❌ | ❌ | ✔✔✔ | ❌ | ✔✔✔ | ❌ |

Usage Guide:

Before use

Ensure the blade specification is suitable for the stone material being cut. Inspect for cracks, segment damage or uneven wear. Confirm correct rotation direction and bore compatibility with the bridge saw spindle. Wear appropriate PPE and ensure all machine guards are in place.

During use

Allow the blade to cut at a steady feed rate without excessive force. Maintain consistent water flow where applicable and avoid sudden changes in feed pressure. Monitor blade condition during extended cutting cycles.

Wet cutting

Wet cutting is required for bridge saw operation to manage heat and maintain cut quality.

Is the ARIX blade suitable for granite cutting?

Yes. Granite is one of its primary intended applications.

Can this blade be used on quartz materials?

Yes. It is specifically designed for quartz surface cutting.

What is ARIX auto array technology?

It is a structured diamond arrangement where each diamond grain is precisely positioned to support consistent cutting behaviour and uniform wear.

Is this blade suitable for marble or porcelain?

No. It is not intended for marble, porcelain or ceramic materials.

Which machines are compatible with the ARIX blade?

It is designed for bridge saws compatible with 400mm or 450mm blades and 50/60mm bores.

Does the ARIX blade comply with UK safety standards?

Yes. The blade conforms to EN13236.