Brick cutting diamond blade developed for professional contractors cutting soft facing bricks and low-density clay bricks on UK masonry and construction projects.

• Engineered specifically for high-speed cutting in soft brick materials

• Designed for smooth, controlled cutting with extended blade life

• 8mm segment height

• Available in 350x25mm and 450x25mm sizes

• Suitable for floor saw use

• EN13236 compliant

Brick cutting diamond blade developed for professional contractors cutting soft facing bricks and low-density clay bricks on UK masonry and construction projects.

• Engineered specifically for high-speed cutting in soft brick materials

• Designed for smooth, controlled cutting with extended blade life

• 8mm segment height

• Available in 350x25mm and 450x25mm sizes

• Suitable for floor saw use

• EN13236 compliant

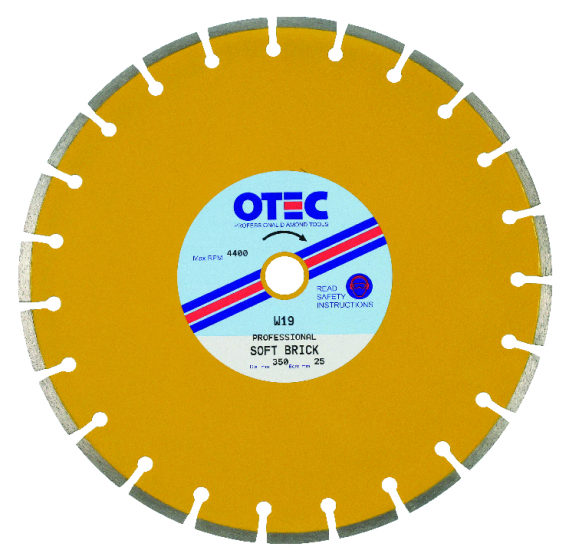

Brick Cutting Diamond Blade – Professional – Soft Brick – 8mm Segment – OTEC W19 is designed for professional brickwork contractors requiring fast, clean and consistent cutting performance in soft clay brick materials.

It is suitable for soft facing bricks and low-density clay masonry units commonly used in UK residential developments, extensions and façade construction. The bond formulation supports efficient cutting speed while maintaining durability across repetitive site work.

The W19 is not suitable for medium, hard or engineering bricks, reinforced concrete, natural stone or metal. It should be specified exclusively for soft brick applications.

Need a different size or even higher performance?

View the complete OTEC range, including the OTEC W6SC - our professional alternative blade for ultra hard brick.

For noise-sensitive environments and indoor workshop use, the OTEC W19SC Professional Silent Centre edition is also available, providing the same precision cutting with significantly reduced operating noise.

✓ Professional bond designed specifically for soft clay brick densities

✓ Supports rapid material removal without excessive surface breakout

✓ Maintains consistent cutting behaviour across repetitive brickwork

✓ Designed to deliver clean edge finishes on facing brick

✓ Balanced construction for stable tracking on floor saws

✓ Optimised for daily professional site use

Specifications Table – OTEC W19

| Specification | Details |

|---|---|

| Product Name | Brick Cutting Diamond Blade – Professional – Soft Brick – 8mm Segment – OTEC W19 |

| Product Code | W19 |

| Segment Height | 8mm |

| Segment Type | Segmented |

| Primary Application | Soft brick |

| Secondary Application | Low-density clay masonry |

| Not Suitable For | Medium brick, hard brick, ultra hard brick, reinforced concrete, stone, metal |

| Safety Standard | EN13236 |

| Recommended Machine Type | Floor saw |

| Use Environment | UK construction and masonry sites |

Variations Table – OTEC W19

| Diameter | Bore | Max RPM | Variation Code |

|---|---|---|---|

| 350mm | 25mm | 4400 rpm* | W19-350/25 |

| 450mm | 25mm | 3500 rpm* | W19-450/25 |

! Max RPM must always be verified against machine rating before use.

Recommended Saw Type by Blade Size – OTEC W19

| Blade Size | Bore | Recommended Saw Type | Typical Site Use |

|---|---|---|---|

| 350mm | 25mm | Floor saw | Soft brick cutting on masonry projects |

| 450mm | 25mm | Floor saw | Larger format brick cutting and site masonry work |

Application:

The Brick Cutting Diamond Blade – Professional – Soft Brick – 8mm Segment – OTEC W19 is suitable for:

- Soft facing brick cutting

- Low-density clay brickwork

- Housing developments and residential construction

- Brick façade and extension projects

- General soft brick masonry tasks

Material Suitability Table – OTEC W19

| Soft Brick | Medium Brick | Hard Brick | Ultra Hard Brick |

|---|---|---|---|

| ✔✔✔ | ❌ | ❌ | ❌ |

Usage Guide:

Before use

Ensure the blade type and specification are suitable for the material being cut. Inspect for cracking, segment detachment, undercutting of the steel centre, uneven wear, or other defects. Confirm correct rotation direction and bore compatibility with the machine spindle. Wear appropriate PPE, including eye protection, and ensure guards are correctly fitted.

During use

Do not apply excessive force. Allow the blade to cut at its designed speed and take regular cooling breaks. If overheating occurs, reassess material suitability. A blunt blade may be refreshed by cutting a soft abrasive material such as brick or block.

Wet cutting

If wet cutting is used, ensure a continuous and adequate water supply to both sides of the blade.

Is the W19 suitable for soft facing bricks?

Yes. It is specifically engineered for clean and efficient cutting in soft clay and facing bricks.

Can this blade cut engineering bricks?

No. It is not designed for medium, hard or engineering brick densities.

Is the W19 suitable for reinforced concrete?

No. It must not be used on reinforced or structural concrete.

What machines are compatible with the W19?

It is suitable for floor saws compatible with either 350mm or 450mm blades with a 25mm bore, within the rated RPM.

Does the W19 comply with UK safety standards?

Yes. The blade conforms to EN13236.

Can this blade be used for wet cutting?

Yes. If wet cutting is used, a continuous water supply should be applied to both sides of the blade.