Hard materials diamond blade developed for professional contractors cutting very hard and dense construction materials on UK construction and infrastructure sites.

• Cooling holes for improved heat control during cutting

• Semi-transparent core for better cutting line visibility

• 10mm segment height with superior turbo segment design

• Available in 115/125/230x22, 300/350x20mm, & 350X25mm sizes

• EN13236 compliant

Hard materials diamond blade developed for professional contractors cutting very hard and dense construction materials on UK construction and infrastructure sites.

• Cooling holes for improved heat control during cutting

• Semi-transparent core for better cutting line visibility

• 10mm segment height with superior turbo segment design

• Available in 115/125/230x22, 300/350x20mm, & 350X25mm sizes

• EN13236 compliant

Hard Materials Diamond Blade – Super Premium – 10mm Segment – OTEC LT10R is a super premium diamond blade developed for professional use on UK construction, infrastructure, and civil engineering sites where very hard materials place increased demands on cutting performance.

It is intended for contractors and site operatives working with hard concrete, granite, hard natural stone, clay products, and engineering bricks. The blade is also capable of cutting metal, making it suitable for mixed-material site environments where versatility is required.

The LT10R is not recommended for asphalt or highly abrasive materials. It should not be specified for asphalt, green concrete, render, cement screed, or lignacite blocks, and should be used within its intended hard-materials application range.

On UK construction and infrastructure sites where very hard materials and occasional metal elements are encountered together, maintaining stable cutting performance without frequent blade changes is critical. Hard Materials Super Premium Diamond Blade – OTEC LT10R is intended for use in these demanding mixed-material site conditions.

✓ Engineered for fast, stable cutting of very hard materials

✓ Supports reliable performance on hard concrete, granite, and natural stone

✓ Reinforced flange design contributes to blade stability during demanding cuts

✓ Turbo segment profile supports smooth cutting action across varied materials

✓ Capable of cutting metal without compromising operator safety

✓ Suitable for universal site use where material types may vary

✓ Developed for consistent performance on UK construction and infrastructure sites

Specifications Table

| Specification |

Details |

|---|---|

| Product Name |

Hard Materials Diamond Blade – Super Premium – 10mm Segment – OTEC LT10R |

| Product Code |

LT10R |

| Segment Height |

10mm |

| Segment Type |

Turbo segment |

| Primary Application |

Very hard materials |

| Secondary Application |

Concrete and general construction materials |

| Suitable Materials |

Very hard concrete, granite, hard natural stone, engineering bricks |

| Not Suitable For |

Asphalt, green concrete, render, cement screed, lignacite blocks |

| Safety Standard |

EN13236 |

| Use Environment |

UK construction, infrastructure, and mixed-material sites |

| Longevity / Wear Notes |

Designed for fast cutting and stable performance on hard materials |

Variations Table

| Diameter | Bore | Max RPM | Variation Code |

|---|---|---|---|

| 115mm | 22mm | 13200 rpm | LT10R-115/22 |

| 125mm | 22mm | 12250 rpm | LT10R-125/22 |

| 230mm | 22mm | 6650 rpm | LT10R-230/22 |

| 300mm | 20mm | 6400 rpm | LT10R-300/20 |

| 350mm | 20mm | 5400 rpm | LT10R-350/20 |

| 350mm | 25mm | 5400 rpm | LT10R-350/25 |

Recommended Saw Type by Blade Size – OTEC LT10R

| Blade Diameter | Typical Bore | Recommended Saw Type | Common Site Use |

|---|---|---|---|

| 115mm | 22mm | Angle grinder | General site cutting, masonry and hard materials |

| 125mm | 22mm | Angle grinder | Regular site use, deeper cuts than 115mm |

| 230mm | 22mm | Large angle grinder | Heavy-duty hand-held cutting, thicker materials |

| 300mm | 20mm | Petrol cut-off saw / bench saw |

Floor cutting, slabs, blocks, site cutting |

| 350mm | 20mm | Petrol cut-off saw | Deep cutting in concrete and hard materials |

| 350mm | 25mm | Floor saw | Continuous cutting, controlled site operations |

The Hard Materials Diamond Blade – Super Premium – 10mm Segment – OTEC LT10R is suitable for:

-

Very hard concrete and dense concrete products

-

Granite and hard natural stone

-

Engineering bricks and hard clay products

-

Reinforced concrete structures

-

General construction products such as slabs, kerbs, and pavers

-

Occasional metal cutting where required

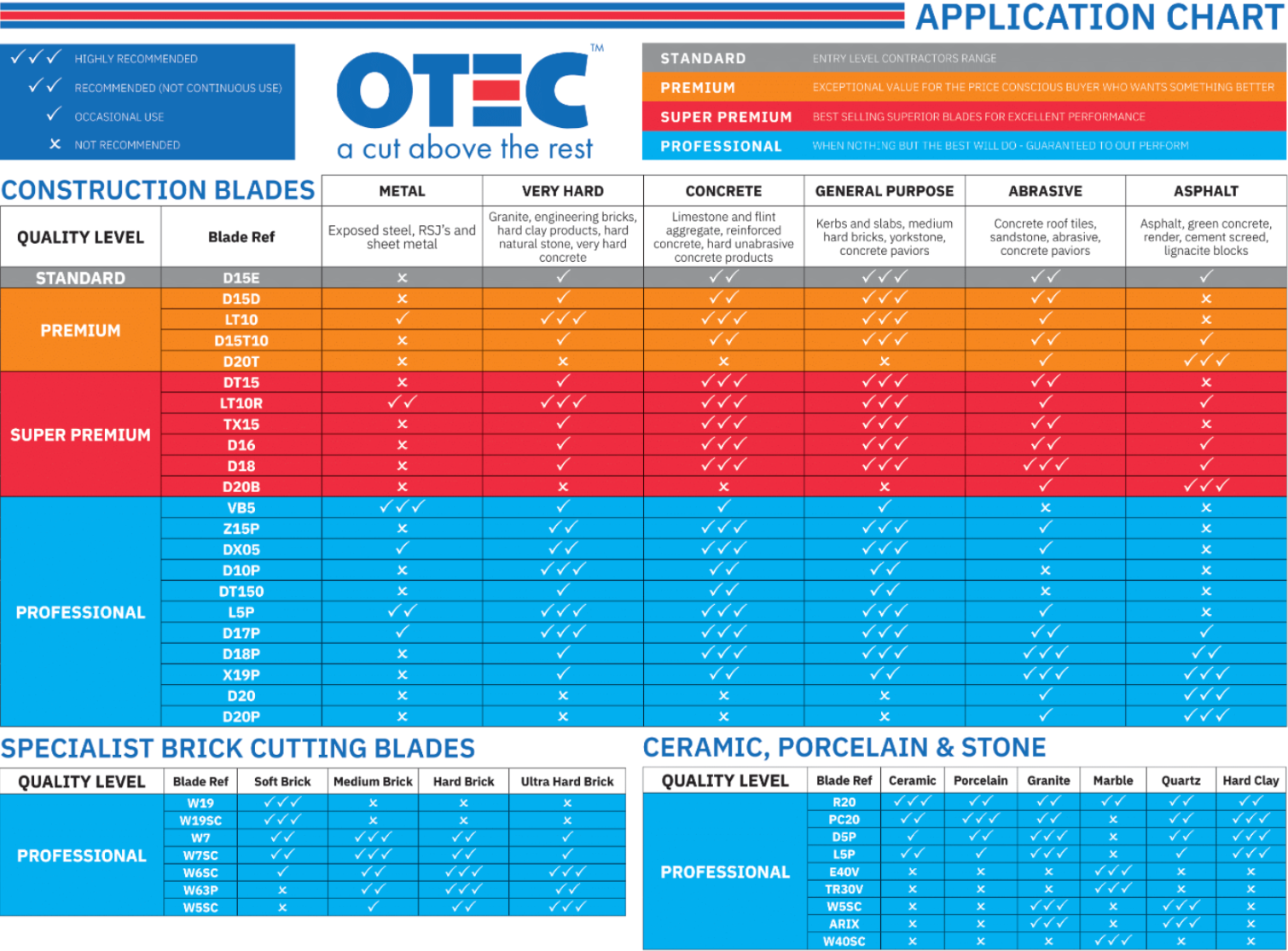

Material Suitability Table – OTEC DT15

| Material Category | Typical Materials Included | Suitability |

|---|---|---|

| Metal | Exposed steel, RSJs, sheet metal, ductile iron pipe, rebar, fibreglass, plastic pipe | ✔✔ |

| Very Hard | Granite, engineering bricks, hard clay products, hard natural stone, very hard concrete | ✔✔✔ |

| Concrete | Limestone and flint aggregate, reinforced concrete, hard unabrasive concrete products | ✔✔✔ |

| General Purpose | Kerbs and slabs, medium hard bricks, yorkstone, concrete paviors | ✔✔✔ |

| Abrasive | Concrete roof tiles, sandstone, abrasive concrete paviors | ✔ |

| Asphalt | Asphalt, green concrete, render, cement screed, lignacite blocks | ❌ |

Before use:

Ensure the blade specification is suitable for the material being cut. Inspect the blade for cracking, segment damage, undercutting of the steel core, uneven wear, or other defects. Confirm that the rotation direction matches the arrow on the blade and that the bore size matches the machine spindle. Wear appropriate PPE and ensure machine guards are correctly fitted.

During use:

Do not apply excessive force when cutting. Allow the blade to cut at its designed speed and take regular cooling breaks. If overheating occurs, reassess material suitability. A blunt blade may be refreshed by cutting a soft abrasive material such as brick or block. Ensure the material being cut is firmly secured and frequently check the blade for signs of damage.

Wet cutting:

If wet cutting is used, ensure a continuous and adequate water supply is applied to both sides of the blade.

Is the OTEC LT10R suitable for cutting very hard materials?

Yes. The LT10R is designed for very hard and dense materials such as granite, engineering bricks, hard clay products, and very hard concrete.

Can this blade be used on reinforced concrete?

Yes. Reinforced and hard unabrasive concrete fall within the intended application range of the LT10R.

Is the LT10R suitable for metal cutting?

It can be used for occasional metal cutting, including exposed steel and rebar, where site conditions require versatility. It is not intended as a dedicated metal cutting blade.

Can this blade be used for asphalt cutting?

No. The LT10R is not suitable for asphalt, green concrete, render, cement screed, or other highly abrasive materials.

What machines can the LT10R be used on?

Depending on blade diameter and bore, the LT10R is suitable for use on angle grinders, large angle grinders, petrol cut-off saws, and floor saws, provided maximum RPM limits are respected.

Is this blade compliant with UK safety standards?

Yes. The LT10R is manufactured in accordance with EN13236, the recognised safety standard for diamond blades used on UK construction sites.

Don't think this is the right blade for you? No worries, we have the blade you're looking for!

Please use the chart below to find the perfect blade for you - simply put the Blade Ref in the search bar and add it to your order!